Description

STANDARD EQUIPMENT

Accessories

1) Coolant through the spindle capability (1000 psi capable) *1000 psi pump is not included

2) Coolant Chip Wash Gun

3) MPG Handle

4) 4th axis pre wiring only (Drivers and motor excluded)

5) Signal lamp (R/G/Y), 3 color)

6) Spindle cooler (Jacket Cooling)

7) Lubrication oil separation tank

8) Full enclosure

9) Lubrication system

10) Pneumatics system

11) Adjust bolt, block & plate

12) Tool kit & box

13) Work light

14) 10.4 inch LCD screen

15) Operation manual & parts list

Control:

16) Fanuc OiMD Control

17) Manual Guide i

18) Ethernet Function

19) Helical Interpolation

20) Rigid Tapping

21) Door interlock

22) Hwacheon AI Nano Contour Control (HAI) -40 block buffer

23) Part program storage length 1,280M(512kb)

Hwacheon Programming:

24) HECC (Hwacheon Efficiency Contour Control System)

25) HTLD (Hwacheon Tool Load Detection)

26) OPTIMA-HTLD (OPTIMA Tool Load Detection System

27) HSDC-(Hwacheon Spindle Displacement Control)

28) HTDC-(Frame Displacement Control)

MACHINE SPECIFICATIONS

TRAVEL

X-axis Stroke (longitudinal movement of Spindle) mm(inch) 610 (24.02”)

Y-axis Stroke (Cross movement of Table) mm(inch) 430 (16.93”)

Z-axis Stroke (Vertical movement of Spindle) mm(inch) 570 (22.44”)

Distance from table surface to spindle gauge plane mm(inch) 150 (5.91”) ~ 720 (28.35”)

Distance between columns to spindle Center mm(inch) 535 (21.06”)

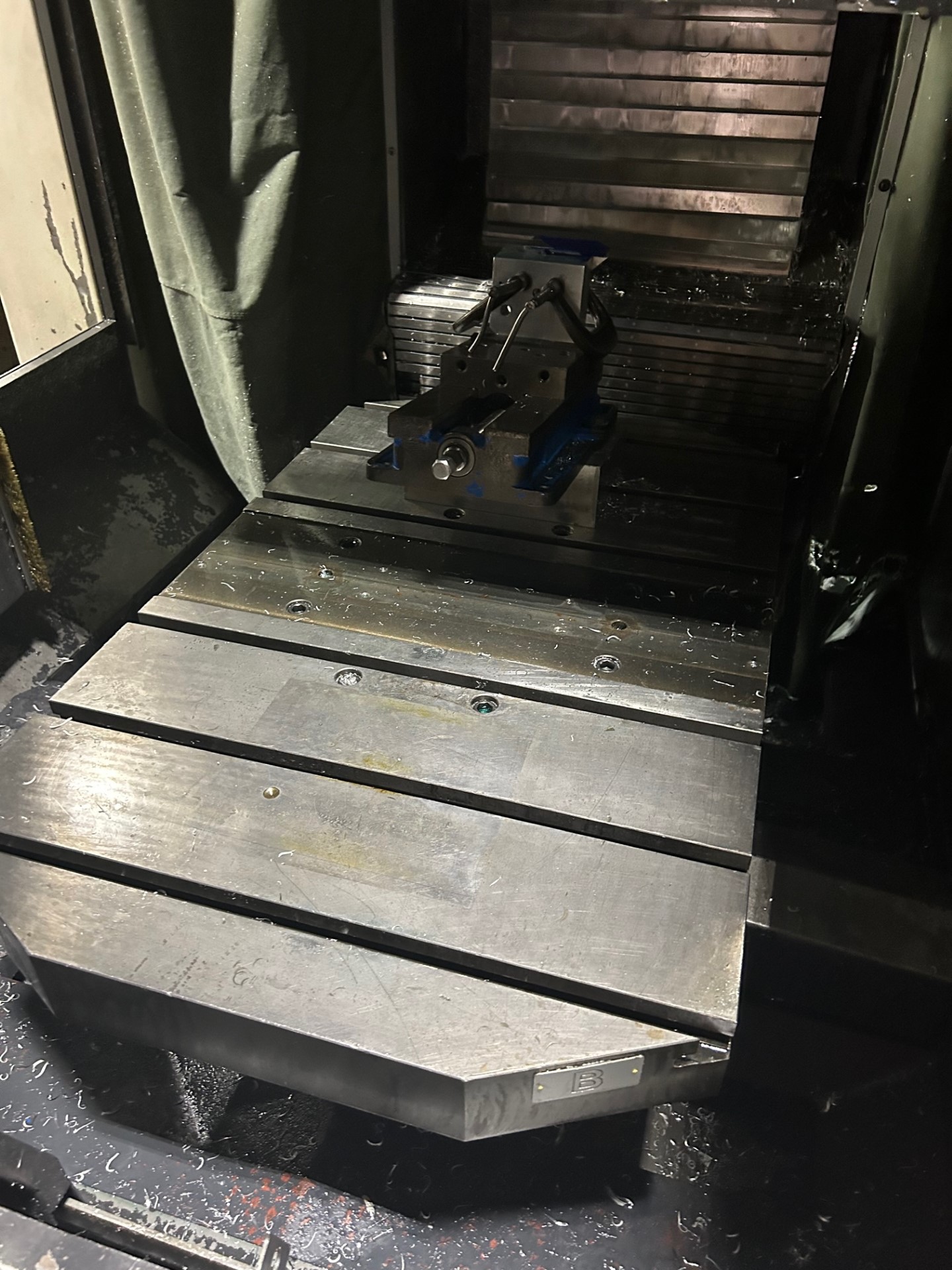

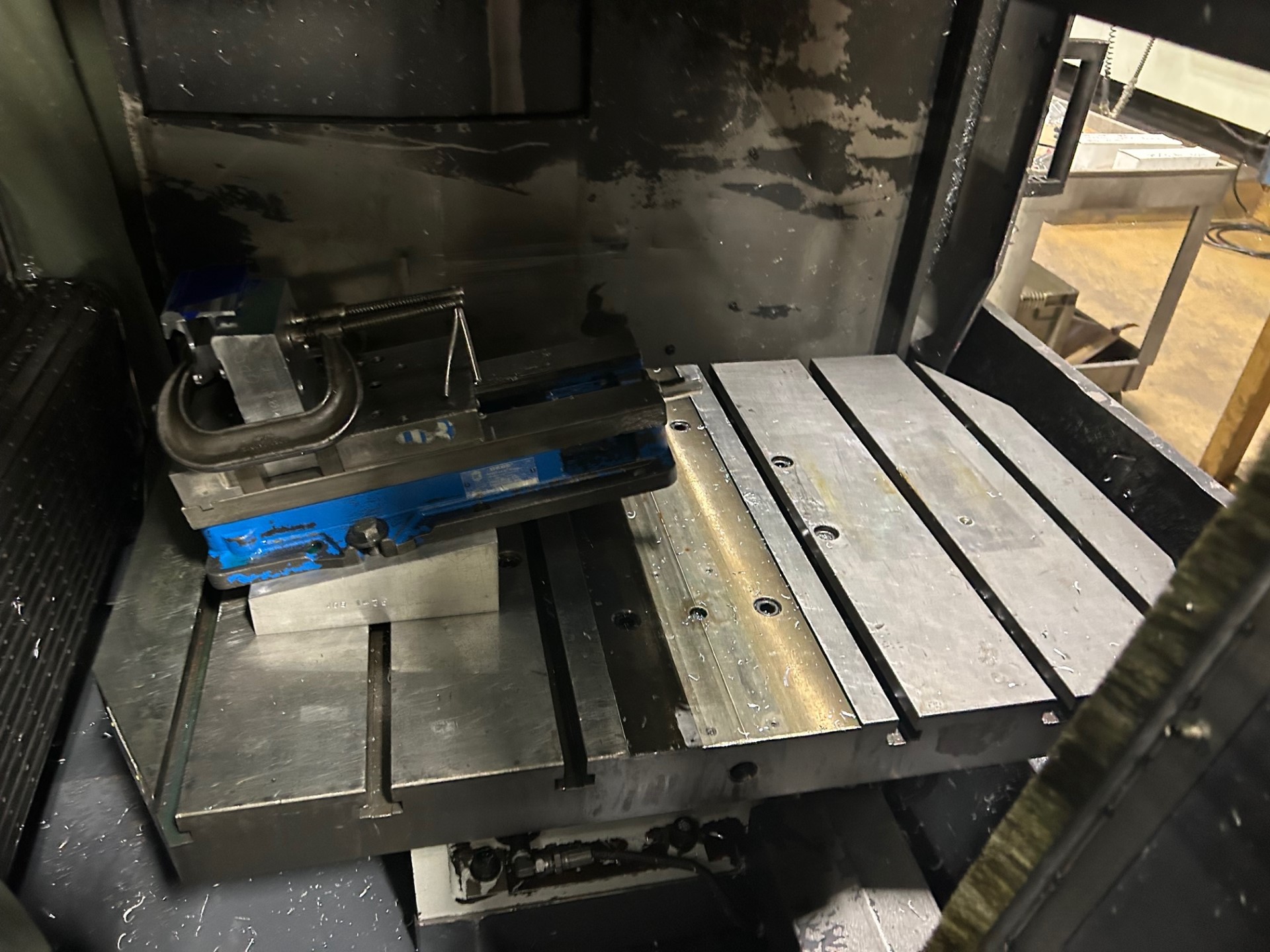

TABLE

Working surface mm(inch) 2ea – 650(25.59”) x450(17.72”)

Table loading capacity kgf(lbf) 2ea – 300 (661)

Table surface configuration (T slots WxP –No. of slots) mm(inch) 2-18 (0.71”) x150(5.91”) 3ea

APC Index Time (180°) sec 6

SPINDLE

Max. spindle speed rpm 10,000

Spindle Motor kW(HP) 15/11 (20/15)

Type of spindle taper hole – ISO#40, 7/24 Taper (BT-40)

Spindle bearing inner diameter mm(inch) Ø70 (2.76”)

Method of Spindle lubrication & cooling – Grease Lub. + Jacket Cooling

FEEDRATE

Rapid Speed (X/Y/Z) m/min(ipm) 40 (1,575) / 40 (1,575) / 40 (1,575)

Feedrate (X/Y/Z) mm/min(ipm) 1~24,000 (945)

ATC

Type of tool shank – MAS-403 BT40 (Opt.:CAT40)

Type of pull stud – MAS P40T-1 (45˚)

Tool storage capacity ea 24

Max. tool diameter [without adjacent tools] mm(inch) Ø90 (3.54”) / Ø150 (5.91”)

Max. tool length mm(inch) 300 (11.81”)

Max. tool weight kgf(lbf) 8 (17.64)

Method of tool selection – Memory Random

Method of operation (Magazine/Swing arm) – Servo Motor / Geared Motor

Tool changing time (Tool to Tool) sec 1.5

Tool changing time (Chip to Chip) sec 4

Motor

Feed motor (X/Y/Z) kW(HP) 7 (9.4) / 7 (9.4) / 7 (9.4)

Coolant motor (Spindle) kW(HP) 0.4 (0.54)

Coolant motor (chip brushing) kW(HP) 0.9 (1.2)

Spindle cooler (50/60Hz) – Inverter type kW(HP) 0.18 (0.24)

Hydraulic motor kW(HP) 2.2 (2.95)

Power Source

Electric power supply kVA 50

Compressed air supply (Pressure x Consumption) – 5~7Kgf/㎠ x 690Nℓ/min

TANK CAPACITY

Lubrication ℓ(gal) 6 (1.59)

Spindle cooling ℓ(gal) 20 (5.28)

Coolant ℓ(gal) 400 (105.7)

Hydraulic ℓ(gal) 15 ( 3.96)

MACHINE SIZE

Height mm(inch) 2,670 (105.12”)

Floor space (length × width) mm(inch) 4,130 (162.6”) x 2,090 (82.28”)

Weight kgf(lbf) 7,500 (16,535)

NC CONTROLLER Fanuc 0i-MD